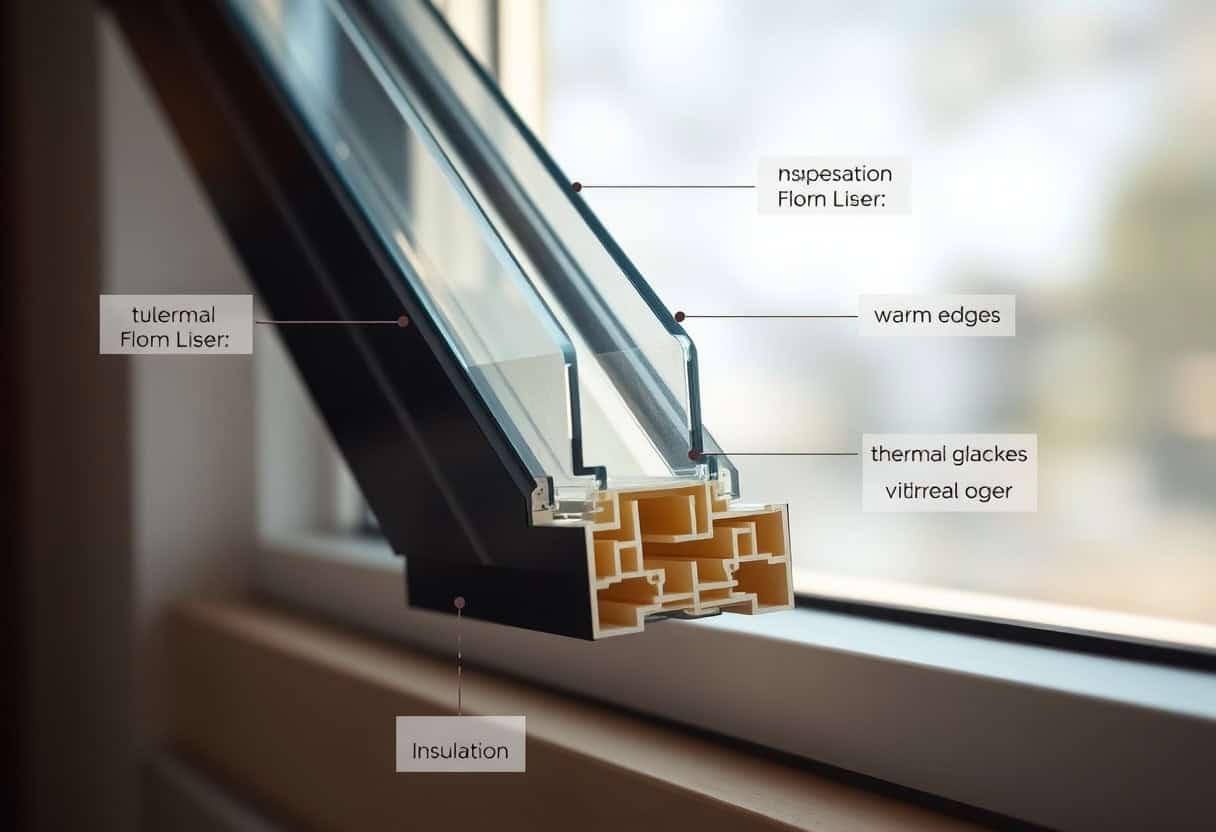

Many homeowners underestimate the impact of thermal breaks and warm-edge spacers on their energy efficiency. By incorporating these elements into your uPVC glazing, you can achieve significant energy savings while also improving the overall comfort of your home. Understanding how these technologies work together to reduce heat transfer will empower you to make informed decisions about your glazing solutions, ultimately leading to better performance and lower energy bills. Discover how embracing these innovations can lead to a more sustainable and cost-effective living environment.

Understanding Thermal Breaks

The importance of thermal breaks in glazing systems cannot be overstated, as they significantly enhance energy efficiency by reducing heat transfer between the interior and exterior of your building. By integrating thermal breaks, you can achieve improved insulation, contributing to a more comfortable environment and lower energy costs.

Definition and Function

For thermal breaks, their primary role is to provide a barrier that limits the transfer of heat through materials such as metal frames, thereby enhancing the overall energy performance of your glazing system.

Types of Thermal Breaks

For understanding the various types of thermal breaks, consider the following:

| Type | Description |

| Polymer Thermal Breaks | Utilise materials with low thermal conductivity for optimal performance. |

| Composite Thermal Breaks | A combination of materials that offer enhanced durability and insulation. |

| Insulated Metal Thermal Breaks | Metal frames featuring insulation to reduce thermal bridging. |

| Structural Thermal Breaks | Designed to maintain the structural integrity while preventing heat loss. |

| Continuous Thermal Breaks | A seamless solution to maximise performance and prevent condensation. |

Any type you choose can have a significant impact on your structure’s overall energy efficiency.

Types of thermal breaks play a pivotal role in maintaining the balance between structural sustainability and energy efficiency. Each type has its own benefits, tailored for specific applications depending on your needs. You might opt for polymer thermal breaks if you seek lightweight solutions, or consider composite thermal breaks for enhanced stability. For external applications, insulated metal thermal breaks could be beneficial due to their strength and compatibility. Ultimately, selecting the appropriate type ensures you achieve maximum performance in your glazing system.

| Type | Benefits |

| Polymer Thermal Breaks | Lightweight and effective; reduces thermal transference. |

| Composite Thermal Breaks | Sturdy, offering excellent insulation properties. |

| Insulated Metal Thermal Breaks | Ideal for external frames; combines strength and insulation. |

| Structural Thermal Breaks | Supports overall structure while minimizing heat loss. |

| Continuous Thermal Breaks | Offers seamless installation for enhanced insulation and control. |

Any choice should factor in your specific requirements and the intended application for optimal energy savings.

The Role of Warm-Edge Spacers

It is necessary to understand that warm-edge spacers are designed to enhance the thermal efficiency of double and triple glazing. These innovative spacers reduce heat transfer between the interior and exterior, contributing significantly to achieving energy savings. By incorporating warm-edge technology in your uPVC glazing, you can maximise comfort while potentially lowering your energy bills. Discover more in The Importance of Energy Efficient Windows.

Benefits of Warm-Edge Technology

Beside reducing energy costs, warm-edge technology offers improved thermal performance, decreased condensation, and a longer lifespan for your windows. You will notice enhanced comfort levels in your home due to minimised cold spots, ensuring a more consistent indoor temperature throughout the year.

Comparison with Traditional Spacers

Comparison of Warm-Edge and Traditional Spacers

| Feature | Warm-Edge Spacers |

|---|---|

| Thermal Conductivity | Low |

| Condensation Risk | Reduced |

| Durability | Higher |

| Energy Savings | Greater |

Against traditional spacers, warm-edge spacers significantly outperform in various areas such as thermal conductivity and durability, which directly affect your overall window performance. When you choose warm-edge technology, you mitigate issues associated with condensation, ensuring a healthier environment in your living space.

Traditional Spacers vs Warm-Edge Spacers

| Aspect | Traditional Spacers |

|---|---|

| Thermal Performance | Inferior |

| Energy Efficiency | Less Effective |

| Cold Bridging | Higher Risk |

| Environmental Impact | More Significant |

Traditional spacers tend to have a higher thermal conductivity, which can lead to greater heat loss in your property. This not only impacts your energy bills but also contributes to potential condensation problems. By understanding these differences, you can make an informed decision that enhances your home’s efficiency and comfort.

Energy Efficiency in uPVC Glazing

You may not realise the significant impact energy efficiency has on your uPVC glazing solutions. By investing in high-quality components, such as Warm Edge Spacer Bars | Energy-Efficient Glazing – Edgetech, you can enhance thermal performance, reduce heating costs, and improve overall sustainability. Ensuring your glazing system meets the latest energy-efficient standards will not only benefit your environmental footprint but also generate long-term savings.

How Thermal Breaks Impact Energy Consumption

To understand how thermal breaks influence energy consumption, consider their role in minimising heat loss through thermal bridging. By interrupting pathways where heat can escape, thermal breaks significantly improve the insulation properties of your uPVC frames, leading to a more energy-efficient home. This results in lower energy bills and a comfortable living environment all year round.

The Importance of Warm-Edge Spacers in uPVC

Thermal performance is further enhanced by the implementation of warm-edge spacers in your uPVC glazing systems. These innovative components work by reducing heat transfer across the edge of the glazing unit, which helps maintain a consistent internal temperature. This minimises condensation and improves overall energy efficiency.

In addition, warm-edge spacers provide greater structural integrity to your glazing units, while ensuring improved durability. By enhancing the thermal performance of your windows, they contribute to reducing energy consumption and improving indoor comfort. Opting for warm-edge spacers not only protects against condensation-related damage but also contributes positively to the environment by reducing your carbon footprint. It’s an investment that pays off in both the short and long term.

Installation and Maintenance Considerations

Your installation and maintenance approach significantly impacts the efficiency of thermal breaks and warm-edge spacers in uPVC glazing. Ensuring that components are correctly fitted and regularly inspected will maximise energy savings, while addressing any signs of wear and tear promptly will prevent minor issues from developing into costly repairs. A careful approach to installation and continued maintenance can prove beneficial for your property’s energy performance.

Best Practices for Implementation

The best way to implement your thermal break and spacer systems is to engage with qualified professionals who have experience in uPVC installations. They will ensure that all components are fitted accurately and adhere to recommended guidelines. Follow the manufacturer’s specifications and consider the property’s unique requirements, while ensuring that the installation process remains meticulous and thoroughly planned.

Maintaining Performance and Longevity

Best practices for maintaining your glazing system include regular inspections and cleaning. Check for any damage to seals, as well as dirt accumulation on the spacer bars, which can hinder performance. Addressing these issues quickly can enhance the longevity and insulation properties of your windows.

Even minor neglect can lead to significant problems over time. Regularly inspect seals and spacers for deterioration to maintain optimal performance and energy efficiency. Ensure that you clean the glass and frames without harsh chemicals that could damage the uPVC. Additionally, monitor for condensation between the panes, as this can indicate potential seal failure. By following these maintenance tips, you can ensure your uPVC glazing provides lasting energy savings and functionality.

Case Studies and Real-World Applications

Many successful implementations of thermal breaks and warm-edge spacers have demonstrated remarkable energy savings in uPVC glazing. Here are some notable case studies:

- Case Study 1: A residential project in London reported a 30% reduction in energy bills after upgrading to thermal breaks.

- Case Study 2: A commercial building in Manchester achieved a 40% improvement in energy efficiency, with warm-edge spacers enhancing insulation.

- Case Study 3: An eco-friendly development in Bristol noted a 25% increase in overall energy performance ratings post-installation.

For more insights on the Energy Efficiency Benefits of UPVC Windows, explore our blog.

Successful Projects Utilizing Thermal Breaks

Around the UK, numerous projects effectively utilised thermal breaks to enhance thermal performance. A notable example includes a residential complex where thermal breaks contributed significantly to overall energy efficiency, attracting sustainable certification. These installations have proven to be favourable in both residential and commercial settings, underscoring the versatility of uPVC products.

Measured Energy Savings

Any building owner can benefit from the measured energy savings associated with warm-edge spacers and thermal breaks. Many homeowners report impressive decreases in energy costs, enhancing the comfort of their living spaces while promoting sustainability.

Savings can be significant, with studies indicating that properties employing thermal breaks see reductions in heating demands by up to 30%. This not only lowers your energy bills but also lessens your carbon footprint, making it a win-win for both your finances and the environment. By incorporating innovative materials such as warm-edge spacers, you ensure a better insulation performance, contributing to a more energy-efficient home.

Future Trends in Glazing Technologies

Unlike traditional methods, future glazing technologies are focusing on sustainability and energy efficiency. Innovations such as smart glass, which can adapt to changing temperatures, alongside advanced thermal breaks and warm-edge spacers, will significantly enhance your uPVC glazing systems. These technologies not only reduce your energy bills but also contribute to a more environmentally friendly approach to building design.

Innovations in Thermal Break Technology

Technology is evolving rapidly in the field of thermal break solutions, enabling better insulation and energy efficiency in glazing systems. New materials and manufacturing processes are being developed that improve thermal performance, ensuring that your uPVC windows and doors are capable of withstanding extreme weather conditions. This innovation ultimately leads to substantial savings on energy costs.

Evolving Standards and Regulations

Between advancements in technology and a growing awareness of environmental issues, the standards and regulations governing glazing systems are becoming more stringent. It is imperative for you to stay informed about these changes, as they can impact your building projects. Compliance with updated standards not only ensures safety but may also lead to increased financial incentives for energy-efficient construction.

Even with the evolving landscape of glazing standards, ensuring your uPVC installations meet the latest guidelines is vital. Regulations are focused on improving energy efficiency, reducing carbon footprints, and enhancing overall building performance. You could face significant penalties if your projects do not comply with these new rules. Additionally, adhering to these standards can open opportunities for grants and financial incentives, making your investments in energy-efficient glazing even more rewarding.

Final Words

With this in mind, investing in thermal breaks and warm-edge spacers for your uPVC glazing system can significantly enhance energy savings in your home. These innovative solutions not only improve insulation performance but also contribute to a more comfortable living environment by reducing heat loss and minimising condensation. By choosing these energy-efficient options, you can lower your heating costs and elevate the overall sustainability of your property, ensuring your investment works harder for you.

FAQ

Q: What is a thermal break and how does it benefit uPVC glazing?

A: A thermal break is a layer of insulating material that separates two conductive materials, such as the outer frame and the inner frame of a window. In uPVC glazing, thermal breaks reduce heat transfer, thereby enhancing energy efficiency. By minimising the flow of heat, these breaks help maintain a stable indoor temperature, leading to reduced energy consumption for heating and cooling.

Q: How do warm-edge spacers contribute to energy savings in glazing?

A: Warm-edge spacers are used in double or triple glazing units to reduce the thermal bridge at the edge of the glass. They are crafted from materials that have a lower thermal conductivity compared to traditional metal spacers. By limiting heat loss at the edges of the glazing, warm-edge spacers help to keep the interior temperatures more stable. This results in less energy being required for heating during winter and cooling during summer, thus contributing to overall energy savings.

Q: Can I retrofit thermal breaks and warm-edge spacers in existing windows?

A: Retrofitting thermal breaks and warm-edge spacers in existing windows can be challenging, as these features are typically integrated during the manufacturing process of new glazing units. However, replacing old windows with energy-efficient uPVC glazing that includes these features is often a more practical solution. This ensures optimal insulation properties and enhances the overall energy performance of the building.

Q: Are there any maintenance requirements for windows with thermal breaks and warm-edge spacers?

A: Windows equipped with thermal breaks and warm-edge spacers generally require minimal maintenance. Regular cleaning of the glass and checking seals for any signs of wear are advisable to maintain efficiency. Ensuring that drainage channels are clear and free from debris will also help preserve the functionality of the window system. Professional inspections may be recommended periodically to guarantee that the thermal performance remains optimal.

Q: What role do thermal breaks and warm-edge spacers play in reducing condensation?

A: Thermal breaks and warm-edge spacers play a significant role in reducing condensation in glazing units. By maintaining warmer temperatures at the edges of the glass, the likelihood of moisture forming on cold surfaces is decreased. This helps to mitigate condensation, which can lead to mould growth and damage to window frames over time. Therefore, incorporating these features not only enhances energy efficiency but also promotes a healthier indoor environment.